The working principle of insulation revolves around the concept of thermal resistance. Insulation materials work by trapping air or other gases within their structure, as these gases are poor conductors of heat. This trapping of air minimizes the convective and conductive heat transfer through the building envelope.

The Role Of R-Value In Insulation Performance

The effectiveness of insulation is primarily measured by its R-value, which stands for resistance value. The R-value measures an insulation material’s ability to resist heat flow. The higher the R-value, the greater the insulation’s effectiveness. This means that materials with higher R-values are better at insulating than those with lower R-values, leading to improved energy efficiency in buildings.

R-values are determined by several factors, including the type of insulation material, its thickness, and its density. For instance, thicker and denser insulation materials generally offer higher R-values. It’s important to note that the R-value needed for optimal energy efficiency varies by location, as different climates have different insulation requirements to achieve the best thermal comfort and energy savings.

Types Of Insulation

Choosing the right type of insulation for your home or building is a crucial decision that affects energy efficiency, comfort, and even the overall environmental impact of the property.

In this section, we will explore various types of insulation, ranging from common options like fiberglass, cellulose, and spray foam insulation to more specialized choices such as Structural Insulated Panels (SIPs) and Aerogel Insulation. Each type has its own set of pros and cons, and understanding their best use can help you make an informed decision. If you would like to gain more information, you can consult professionals such as https://raycore.com/contractor-build-with-sips/. Let’s dive in.

-

Fiberglass Insulation

Fiberglass insulation is made from excellent glass fibers and is one of the most used types of insulation in residential and commercial buildings. The process involves melting sand and recycled glass to form molten glass, which is then spun into fibers. These fibers are woven together to create insulation materials in the form of batts, rolls, or loose-fill.

Pros Of Fiberglass Insulation

- Cost-Effective: Fiberglass is one of the most affordable insulation materials available.

- Versatile: It can be used in various parts of a building, including walls, attics, and floors.

- Fire Resistance: Fiberglass is naturally non-combustible, enhancing fire safety in buildings.

- Easy To Install: This format is ideal for do-it-yourself (DIY) projects, particularly with batts and rolls.

Cons Of Fiberglass Insulation

- Irritation: Handling fiberglass can irritate the skin, eyes, and respiratory system.

- Settling: Over time, fiberglass insulation can settle, reducing its effectiveness.

- Moisture Susceptibility: When wet, fiberglass can lose insulating properties and may promote mold growth.

Best Uses

Fiberglass is best used in dry, accessible areas where its fire resistance and cost-effectiveness are major advantages, such as in walls, attics, and floors of residential and commercial buildings.

-

Cellulose Insulation

Cellulose insulation is made from recycled paper products, primarily newspaper, treated with fire retardants. The material is either blown into place or installed as dense-pack in walls and attic spaces.

Pros Of Cellulose Insulation

- Eco-Friendly: Made from up to 85% recycled materials, making it an environmentally sustainable choice.

- Energy-Efficient: Offers superior air-sealing capabilities, reducing energy costs.

- Sound Insulation: Excellent sound absorption properties.

- Fire Resistance: Treated with fire retardants to slow down the spread of fire.

Cons Of Cellulose Insulation

- Settling: This can settle over time, potentially reducing its effectiveness.

- Moisture Sensitivity: This can absorb moisture, affecting its insulating properties and leading to mold growth.

Best Uses

Cellulose is ideal for attic floors and dense-pack applications in walls, especially in retrofit projects and for those looking for an eco-friendly insulation option.

-

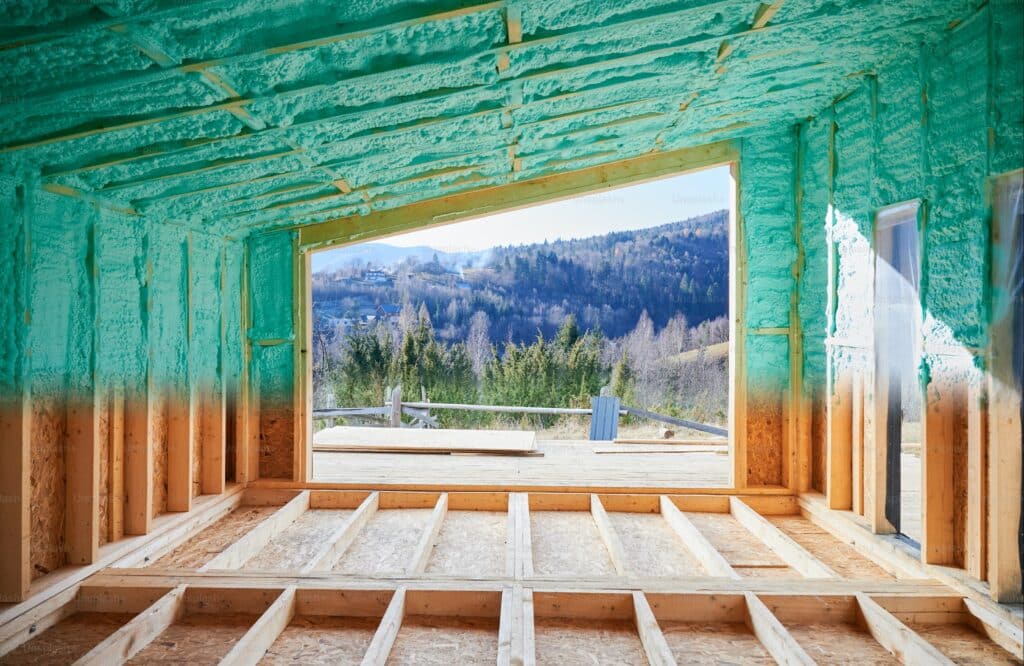

Spray Foam Insulation

Spray foam insulation is a chemical product that expands and hardens into a foam. Two main types are open-cell (less dense and cheaper) and closed-cell (denser and provides a vapor barrier).

Pros Of Spray Foam Insulation

- High R-Value: Offers superior thermal resistance, especially closed-cell foam.

- Air Sealing: Excellent at sealing leaks and gaps, improving energy efficiency.

- Moisture Barrier: Closed-cell foam is impervious to water, preventing moisture problems.

- Structural Support: Closed-cell foam can add strength to the building structure.

Cons Of Spray Foam Insulation

- Cost: More expensive than other types of insulation.

- Installation: Requires professional installation due to the chemicals involved.

- Potential For Off-Gassing: Some spray foams can emit harmful chemicals during and after installation.

Best Uses

Spray foam is best used when air sealing is critical, such as in gaps, cracks, and around windows and doors. Closed-cell foam is suitable for areas prone to moisture.

-

Rigid Foam Board Insulation

Rigid foam board insulation is made from polystyrene, polyisocyanurate (polyiso), or polyurethane. These boards are known for their high-insulating properties and moisture resistance.

Pros Of Rigid Foam Board Insulation

- High R-Value Per Inch: Effective at reducing heat transfer with less thickness required.

- Moisture Resistance: Especially with closed-cell types like polyiso.

- Versatility: It can be used in various applications, including below-grade and exterior insulation.

Cons Of Rigid Foam Board Insulation

- Cost: It’s more expensive than fiberglass or cellulose.

- Installation: Cutting and fitting the boards can be labor-intensive.

- Environmental impact: Some types are made with gases that have a high global warming potential.

Best Uses

Rigid foam excels in insulating basements, crawl spaces, exterior walls, and beneath concrete slabs, offering significant advantages due to its moisture resistance and superior R-value.

-

Reflective Insulation

Reflective or radiant barrier insulation is made from aluminum foil attached to paper or plastic. It works by reflecting radiant heat, reducing heat gain in summer.

Pros Of Reflective Insulation

- Effective In Hot Climates: Reduces cooling costs by reflecting heat away from the building.

- Lightweight: Easy to handle and install.

- Durable: Maintains effectiveness as it doesn’t settle or absorb moisture.

Cons Of Reflective Insulation

- Limited Advantage In Cold Climates: Primarily beneficial for reflecting heat but less effective for retaining heat.

- Critical Installation Requirement: An air gap must be preserved through correct installation for optimal effectiveness.

Best Uses

Reflective insulation is most effective in attics and roofs in hot climates, where it can significantly reduce cooling costs by reflecting solar heat.

-

Mineral Wool Insulation

Mineral wool insulation can be made from rock wool (natural basalt) or slag wool (industrial waste). It’s known for its fire resistance and soundproofing capabilities.

Pros Of Mineral Wool Insulation

- Fire Resistance: Naturally fire-resistant without the need for additional chemicals.

- Sound Insulation: Excellent sound-absorbing properties.

- Water Repellent: Doesn’t absorb water, preventing mold growth.

- Eco-Friendly: Contains a high percentage of recycled content.

Cons Of Mineral Wool Insulation

- Cost: More expensive than fiberglass.

- Irritation: Like fiberglass, it can irritate the skin and respiratory system upon contact.

- Weight: Heavier than other types of insulation, which may be a concern in some applications.

Best Uses

Mineral wool is ideal for fire-prone areas, sound-sensitive environments, and where moisture resistance is needed, such as in external walls, basements, and between floors for sound insulation.

-

Natural Fiber Insulation

Natural fiber insulation is made from renewable resources like cotton (denim), sheep’s wool, and hemp. These materials are treated with fire retardants and insect/rodent repellents.

Pros Of Natural Fiber Insulation

- Eco-Friendly: Made from sustainable and often recycled materials.

- Non-Toxic: Free from harmful chemicals, offering a healthier indoor environment.

- Sound Insulation: Provides good sound absorption.

- Energy-Efficient: Comparable R-values to traditional insulation materials.

Cons Of Natural Fiber Insulation

- Cost: Generally, it’s more expensive than synthetic insulations like fiberglass.

- Availability: It may be harder to find than more common insulation types.

- Moisture Sensitivity: While some treatments enhance moisture resistance, they may still be more prone to moisture than synthetic insulations.

Best Uses

Natural fiber insulation is best used in residential applications where environmental impact, indoor air quality, and energy efficiency are priorities, such as in walls, attics, and ceilings.

Specialized Insulation Types

In building and construction, achieving optimal energy efficiency often requires exploring beyond conventional insulation materials. This exploration leads us to specialized insulation types designed with advanced technologies to cater to specific, often demanding, performance criteria.

-

Structural Insulated Panels (SIPs)

SIPs serve as cutting-edge components for high-efficiency building exteriors, incorporating a foam insulation core flanked by two structural facings, often crafted from oriented strand board (OSB). This combination results in an engineered panel that delivers both insulation and structural support, making it suitable for a variety of applications, including walls, roofs, and floors.

Pros Of SIPs

- Energy Efficiency: SIPs provide high insulation values, leading to significant energy savings.

- Strength: The structural capabilities allow for greater spans and fewer support beams.

- Speed Of Construction: Panels are prefabricated, enabling quicker on-site assembly than traditional building methods.

- Air Tightness: Provides excellent air sealing, reducing energy loss and improving indoor air quality.

Cons Of SIPs

- Cost: Initial costs can be higher than traditional construction methods.

- Specialized Labor: Requires trained professionals for installation to ensure proper sealing and avoid future issues.

- Inflexibility: Alterations or changes to the design can be complex once panels are manufactured and installed.

Best Uses

Projects prioritizing energy efficiency and structural strength benefit most from SIPs, making them perfect for residential and commercial buildings. They are particularly effective in new constructions, where one can seamlessly incorporate their advantages from the design phase.

-

Vacuum Insulation Panels (VIPs)

VIPs use a core material that manufacturers evacuate, seal, and encase in a thin, gas-tight envelope. This technology offers superior insulation performance with minimal thickness since the vacuum greatly diminishes conductive and convective heat transfer.

Pros Of VIPs

- Superior Insulation: It offers a higher R-value per inch than traditional insulation materials.

- Space Efficiency: Its thin profile maximizes usable interior space.

- Weight: It’s lightweight, adding minimal load to structures.

Cons Of VIPs

- High Cost: It’s more expensive than most other insulation types.

- Fragility: The vacuum seal can be punctured, significantly reducing effectiveness.

- Customization Limitations: The panels must be carefully sized and shaped for each application, as cutting or altering them on-site is impossible.

Best Uses

VIPs are ideal for applications where space is at a premium and high insulation values are required, such as refrigeration, transportation of temperature-sensitive goods, and buildings where maximizing interior space is a priority.

-

Aerogel Insulation

Manufacturers create aerogel insulation using silica aerogels, which rank among the lightest solids available. The process involves converting a gel into a solid form, wherein air makes up 99% of its total volume. This distinctive structure endows aerogels with superior insulating properties, highlighted by their remarkably low thermal conductivity.

Pros Of Aerogel Insulation

- High Performance: It provides exceptional thermal insulation with a thin profile.

- Lightweight: It’s very light, imposing minimal structural load.

- Translucency: Some aerogels allow light transmission, which is helpful for daylighting strategies.

Cons Of Aerogel Insulation

- Cost: It can be significantly more expensive than traditional insulation materials.

- Fragility: It can be brittle and difficult to handle and install without causing damage.

- Availability: It’s not widely available as conventional insulation options.

Best Uses

Aerogel insulation is best suited for specialized applications where its unique properties—such as ultra-high insulation value, lightweight, and potential translucency—are critical. This includes high-tech industries, sophisticated building projects, and areas within a building with limited space. Still, high insulation levels are needed, such as in thin walls or glazed areas.

Innovations In Insulation Technology

The landscape of insulation technology is ever-evolving, driven by the need for more efficient, sustainable, and cost-effective solutions. Innovations in this field are improving insulation materials’ thermal performance, addressing broader environmental concerns, enhancing durability, and simplifying installation processes. Here are future trends to watch out for in insulation technology:

-

Smart Insulation

With the advent of smart homes, there’s a growing interest in smart insulation solutions that adapt to environmental conditions. Materials that can change their thermal conductivity based on temperature, humidity, or the time of day could revolutionize energy efficiency in buildings.

-

Recycling And Circular Economy

The push towards sustainability is leading to innovations in recycling insulation materials. Future developments may include more efficient processes for recycling fiberglass and foam insulation or designing new materials that are easier to recycle at the end of their life cycle.

-

Integrated Solutions

Future insulation materials might have integrated functionalities, such as built-in sensors to monitor temperature, moisture levels, or structural integrity. This integration could lead to more intelligent building designs, optimizing energy use and enhancing occupant comfort.

-

Global Warming Potential (GWP) Reduction

As the construction industry focuses on reducing its environmental impact, insulation materials with low GWP are becoming a priority. Future innovations may focus on reducing or eliminating high-GWP gases used in foam insulation production, favoring alternatives with minimal environmental impact.

Insulation technology innovations promise to enhance buildings’ energy efficiency and contribute to a more sustainable and resilient built environment. As these technologies mature and widely adopted, they will play a crucial role in meeting global energy and environmental challenges.

Conclusion

Insulation technology is undergoing a significant transformation, driven by the dual imperatives of enhancing energy efficiency and reducing environmental impact. By embracing these cutting-edge materials and techniques, the construction industry can contribute to creating greener, more energy-efficient buildings that are better adapted to the challenges of the 21st century.